Smart Glass. Smart Glazing. Switchable Glass. Regardless of what we call it, the general definition is “glass that changes to different levels of opacity and transparency on demand for light control”.

If you’re just starting your research on smart glass, you’re probably seeing the two most common types pop up: SPD and PDLC. While industry professionals know the difference between the two, these terms are foreign to most, leaving the majority of people wondering: what differentiates SPD from PDLC? And, which of these two smart glass technologies are right for me?

Here is our drill-down of the key similarities and differences between SPD and PDLC:

The similarities between SPD and PDLC technologies:

- Both technologies are most commonly coated between two pieces of PET-ITO to create a film

- Both films are paired with glass or other transparent materials

- They are both controlled by applying electrical voltage

- When opaque, the glass is turned off. When transparent, the glass is on.

- Opacity is when molecules are randomly aligned, blocking light

- Transparency is when molecules are aligned, letting light shine through

- Both block up to 99% of UV

The key differences that set SPD and PDLC apart:

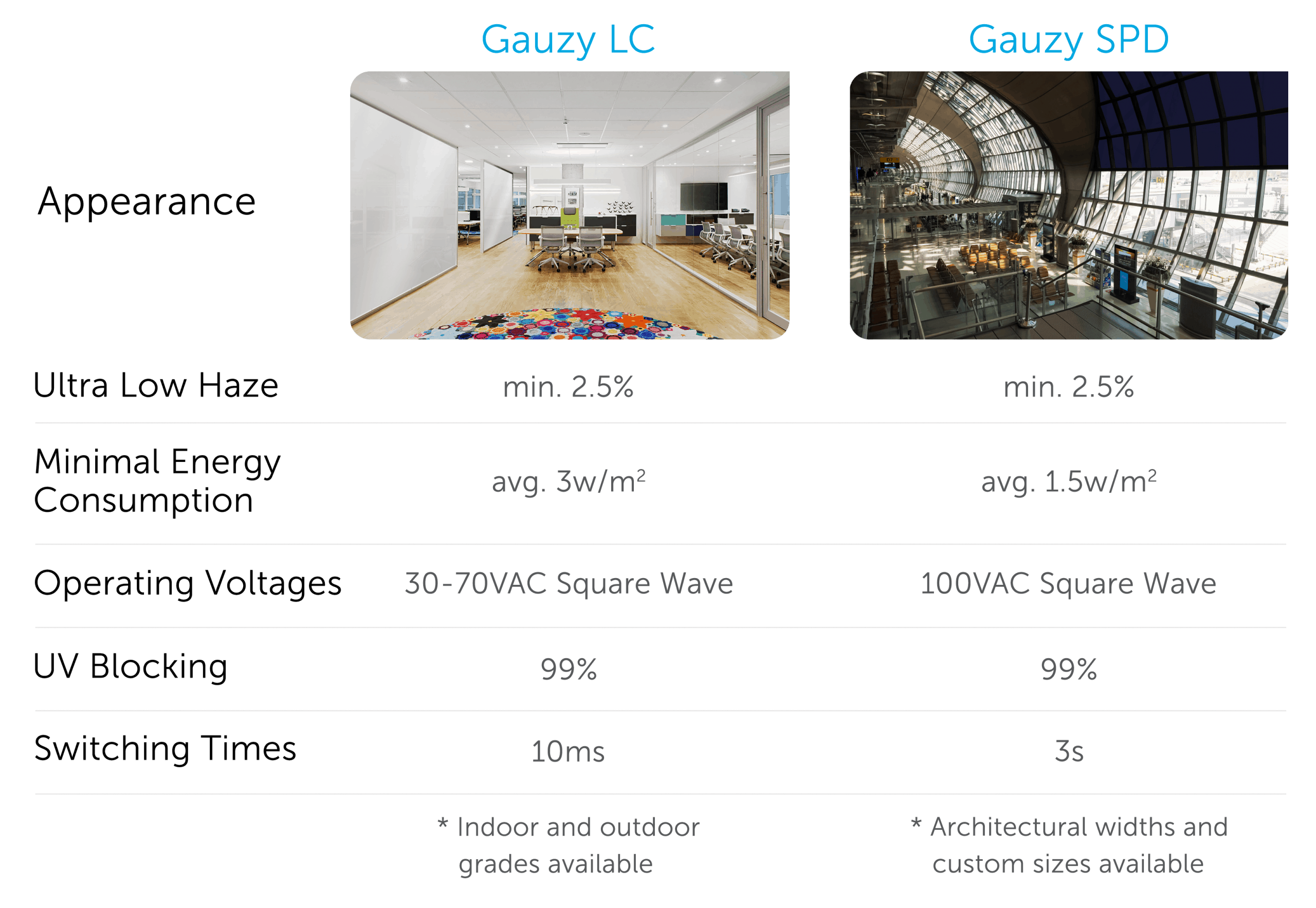

PDLC stands for Polymer Dispersed Liquid Crystal (liquid crystals that are dispersed into a polymer glue-like material). PDLC has high light transmittance (80%), making it ideal for privacy or projection when opaque, and not for tinting.

Liquid Crystal Glass has ultra-fast switching times (10-150ms from on/off and off/on), consumes minimal power (avg. 3W / 2 sqm (6.6 sqf) — less than 1 LED bulb!) — and has ultra-low haze (as low as 2.5% depending on the manufacturer).

SPD stands for Suspended Particle Devices (rod-like particles that are suspended in a matrix). SPD can block up to 99% of light, making it ideal for custom shading in outdoor windows, and not a solid privacy solution. Switching speed is up to 3 seconds, no matter the size of the glass — significantly faster than other active glass technologies used for shading. Haze is as low as 2.5% — depending on post processing and the manufacturer. Because of its shading capabilities, SPD is found in cars, planes, trains, or in architecture as it can contribute to LEED points, making projects greener and more energy efficient.

When Science Meets Your Space

The choice between PDLC or SPD depends on a specific project’s needs and the desired outcome.

Liquid Crystal Glass is typically used by architects and interior designers for interior switchable glass partitions where on-demand privacy or transparency for an open atmosphere is a top priority. The most likely spaces to utilize LC privacy glass are offices, where privacy and light are both essential. Another is glass bathroom enclosures in hotels for a feeling of maximized space, or in storefronts creating dynamic digital displays that turn transparent for 100% utilization of storefront windows when paired with projection.

Because of it’s tinting and shading capabilities, SPD smart glass is outdoor grade, and most commonly found in the automotive sector, creating smart windows in sky facing glass like the sunroof of the McClaren or Mercedes S-Class, which shades or tints to custom degrees for reduced glare, fuel consumption, and solar/energy control within a vehicle.

Two Technologies. One World.

Until today, architects and interior designs were most likely to use Liquid Crystal Glass for interior “WOW Factor” while the transportation industry turned to EDW’s (electronically dimmable windows) with SPD. However, we stand at the beginning of a new era where smart glass is redefining the industry standards.

Material science company Gauzy is now manufacturing SPD with architectural widths making it ideal for skylights, facades, and curtain walls. They are also bringing LC based films outdoors with its High Temp and Solar Reflective technologies. This breakthrough is opening new opportunities for OEM’s and Tier-1 suppliers to integrate PDLC into car windows for location and time based advertising and IR light reflection.

As smart glass technology continues to make its way into mainstream automotive and architectural applications, the way we interact with glass, and light, will change drastically. Both Liquid Crystal Glass and glass with SPD technology, also known as LCG® (light control glass) are key contributors towards the push for integration of smart materials across sectors.

Interested in using PDLC or SPD in a project? Are you a glass industry professional looking to add a new product to your portfolio? Contact Gauzy for more information and an obligation free quote.